The magnetic separator can separate raw materials with different magnetic rigidities, The machine works under the magnetic force and machine force.Magnetic Separators are designed torecover ferromagnetic materials.The separators are available in designs and sizes to provide solutions for all applications. The heart of each separator is the magnetic system with its unique design, which has a proven record of high efficiency.

The Magnetic Separators are available in cyclic design with process vessel diameters smaller than 3mm. Magnetic Separator is one kind of efficient equipment for processing fine, feebly magnetic minerals, such as hematite, limonite, wolfram,ilmenite, and tantalum-niobium, etc. In recent years,it is also more and more applied in purifying quartz, feldspar and nephline. Its magnetic system is a ring-shape chain closed magnetic circuit with energizing coils made of copper tube and cooled internally by water. Grooved plates made of magnetic conductive stainless steel are used as magnetic matrix.

Working Principle

The mineral slurry flows into the cell through box feeder, the mineral particle is loose under the function of water flow of feeder water pipe when they flow into the cell. Affected by magnetic field,the magnetic particle swarm together and form magnetic cluster or chain. With the magnetism of mineral slurry, the magnetic cluster or chain moves toward the magnetic pole, and is absorbed to the cylinder. Because of the polarity of magnetic pole, the revolving directions alternate constantly,and remain fixed when it is working. When the magnetic cluster and chain go round and round along with the cylinder, the mingled gangue and other non-magnetic ore fall down due to the mixing phenomena produced by alternation of magnetic poles, and it is concentrate that is absorbed to the cylinder surface. The concentrate moves to the end of magnetic system where the magnetism is weakest along with the revolving cylinder, and is discharged into concentrate tank by the current ejected by the discharging-ore pipe. The non-magnetic or weak magnetic remained are discharged along with the mineral slurry, and they are gangue.

Advantages

1)Short magnetic circuit,

2)little magnetic flux leakage

3)high magnetic intensity

4)low energy consumption

5)fine beneficiating results

6)simple structure and easy to maintain

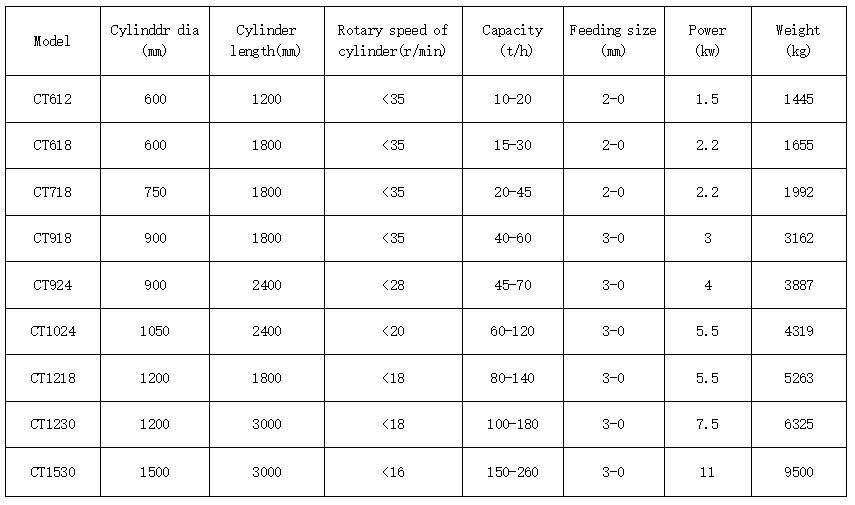

Technical parameters