Advantage

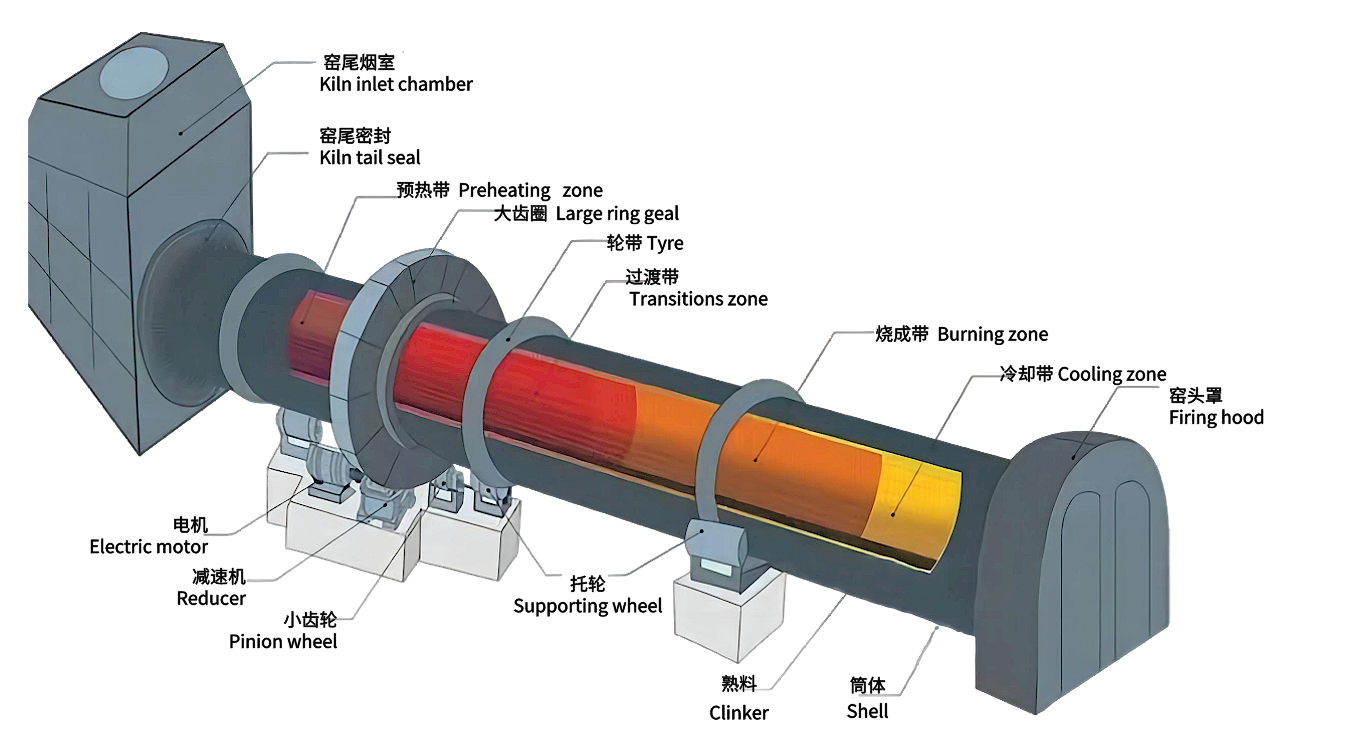

The calcining kiln can be divided by uses into cement rotary kiln, lime rotary kiln, metal magnesium rotary kiln, ceramsite sand rotary kiln, metallurgy rotary kiln.Harmful waste rotary kiln, industrial sludge rotary kiln, etc. according to the use, the models are complete, the annual processing capacity is 100000-1000000 tons, and different models and specifications can be configured according to the needs of customers.

1.High thermal efficiency

Material is fully and evenly heated with fast heat transmission,on the other hand, the material and gas flow reversely, and the heat is fully utilized. The waste gas passes through the preheater at the kiln end, and the heat is reused and dried, which greatly improves the thermal efficiency of the kiln.

2.Energy saving and environmental protection

The rotary kiln is an equipment with high energy consumption, meanwhile has a great impact on the environment. Nationally there is much concerned about the new rotary kiln project. The rotary kiln equipment manufactured by our company has good sealing performance,reasonable equipment configuration and low energy consumption. we are professional manufacturer who are manufacturing energy-saving and environmental protection rotary kiln that strictly following the national environmental protection regulations.

3.High quality of final products

The fuel does not contact with the material directly, which can avoid the pollution of the material.

4.Simple operation and high efficiency

The operation of the rotary kiln system is easy to master, the observation is intuitive and easy, the user can be guaranteed to put into production in a very short time, and the relevant equipment can be designed according to the production requirements of the customer, with high working efficiency.

5.Wide range of raw material particle size

It is suitable for a wide range of particle size of materials, which not only improves the utilization rate of mine resources, but also plays the role of environmental protection and energy saving.