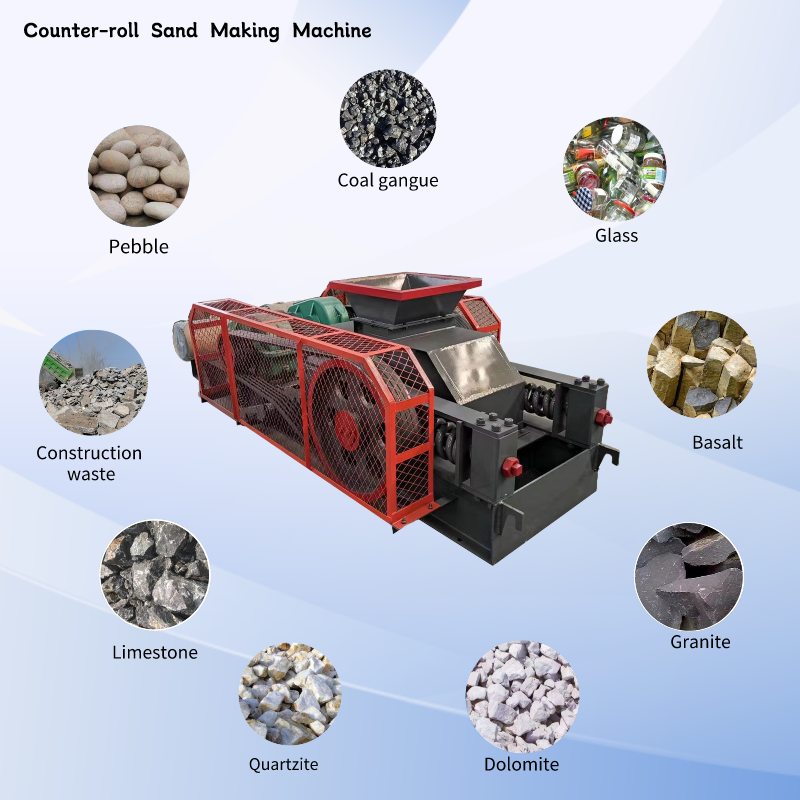

Roller crusher (twin-rell crusher) is suitable for crushing brittle bulk materials in cement, chemical industry, electric power, mining, metallurgy, building materials, refractories, coal mines and other industries. It has large feed size, adjustable feed size and can cruse materials with compressive strength less than 160 MPa.Especially in the coal industry, crushing raw coal with this machine can be directly crushed as long as iron removal, impurity removal, no need to remove gangue. The crushed materials have uniform particle size and low over-crushing rate, thus simphtying the coal preparation process and reducing investment and production costs.

The machine has reliable work, simple maintenance, low operating cost, and adjustable particle size.

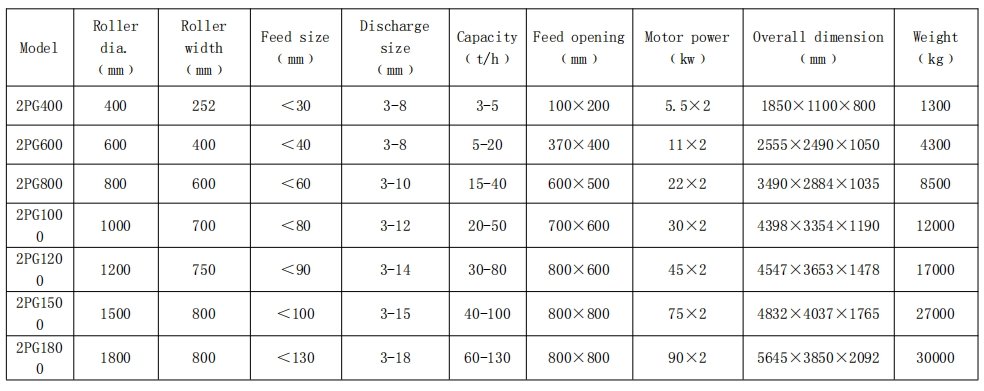

The Main Technical Parameters

The roller crusher is mainly composed of rollers, roller support bearings, compression and adjustment devices, and driving devices. A wedge-shaped or gasket adjustment device is installed between the two rollers, and the top of the wedge-shaped device is equipped with an adjustment bolt. When the adjustment bolt pulls the wedge up, the wedge tops the movable roller from the fixed wheel, that is, the gap between the two rollers becomes larger and the discharge particle size becomes larger. When the wedge goes down, the gap between the two wheels becomes smaller under the action of the compression spring. The particle size of the discharge becomes smaller. The gasket device adjusts the particle size of the discharge by increasing or decreasing the number or thickness of gaskets. When the gasket is increased, the gap between the two rollers becomes larger. When the gasket is reduced, the gap between the two rollers becomes smaller and the particle size of the discharge becomes smaller.

Crushed materials